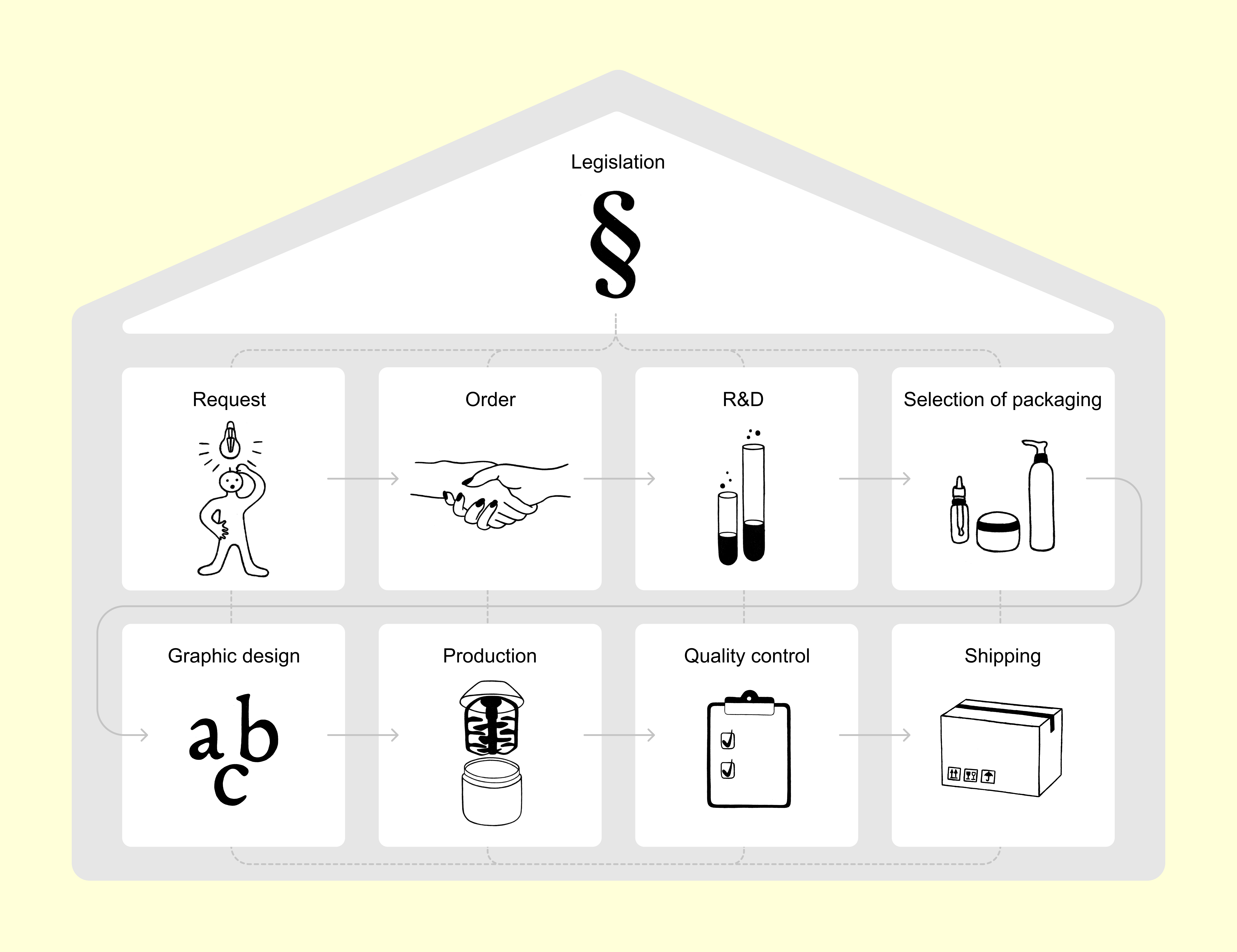

Production from A to Z

We carry out all the steps necessary to manufacture and market the product. From development to production, assembly and dispatch.

Our new production hall is equipped with high-tech machinery, certified lines and other departments that together offer a comprehensive service in the production of cosmetics, food supplements, veterinary products and medical devices.

All in one place with maximum time and cost savings.

Vyrábíme:

-

Cosmetic products

-

Food supplements

-

Veterinary products

-

Medical devices

Our state-of-the-art technological facilities have several modern production lines to produce:

- liquids

- semi-liquids

- powders

The variability of our machinery allows us to fill different types of packaging in desired volumes:

-

Tubes

-

Jars

-

Bottles

-

Pumps

-

Mechanical dispensers

-

Airless packaging

-

Doypacks

-

Sachets

-

Canisters

We provide:

- mixing

- filling

- labelling

- inkjet

- assembly

- foiling

- packing into shipping cartons

- stacking on pallets

- storage in system-controlled warehouses

- logistics services

- and more...

We offer production in the range of complex production activities or in the realization of selected parts.

Each step of production is controlled by the company's software, which ensures the smooth running of the entire process.

We understand the diversity of our customers' needs, therefore you can choose from different types of business cooperation from fully customized production to private label to sophisticated white label.

We're in this together

Throughout the whole process of implementing your project, you will have an expert from our sales department by your side. They will familiarise you with the legal requirements, explain the production process, answer your questions and guide you through the premises where the product will be created. Partnership and open communication with the client is one of the cornerstones of our way of working.

Every step under supervision

A sophisticated quality control system oversees all phases of pre-production, production and post-production. The control mechanisms take place at three levels. Input during the receipt of raw materials, packaging materials and compatibility testing, through the control of production and internal processes, to the control of the output of finished products and the handover of the goods for dispatch to the client.

Production is carried out in accordance with quality management standards:

-

GMP for pharmaceutical manufacturing

-

ISO 9001 Quality Management System

-

ISO 22716 Good Manufacturing Practice for Cosmetic products

-

ISO 13485 Medical Products

-

ISO 14001 Environmental Management

-

HACCP Hazard Analysis and Critical Control Points for the production of food supplements and veterinary products